Please note: This page was last updated before the restoration began, and is kept for archive purposes.

Pipework

This is in very good condition and well-supported, but the build-up of dust is significant. It is now 32 years since the pipework was cleaned, and the dust inevitably affects the speech of the pipes. The situation is most acute on the Great and Pedal Organs.

All pipework will be cleaned and all reeds sent to Harrison & Harrison in Durham to be cleaned and re-set by voicers, with care being taken to preserve the original tone quality. The few damaged pipes in the organ will be repaired. This work will take place between January and July 2016.

In August 2016, once all the pipes are replaced in the instrument, some in new positions, voicers will go through all the pipework in detail to reinstate the correct musical speech and balance – an important and sensitive task, for which quiet conditions are needed. This work can take up to six weeks.

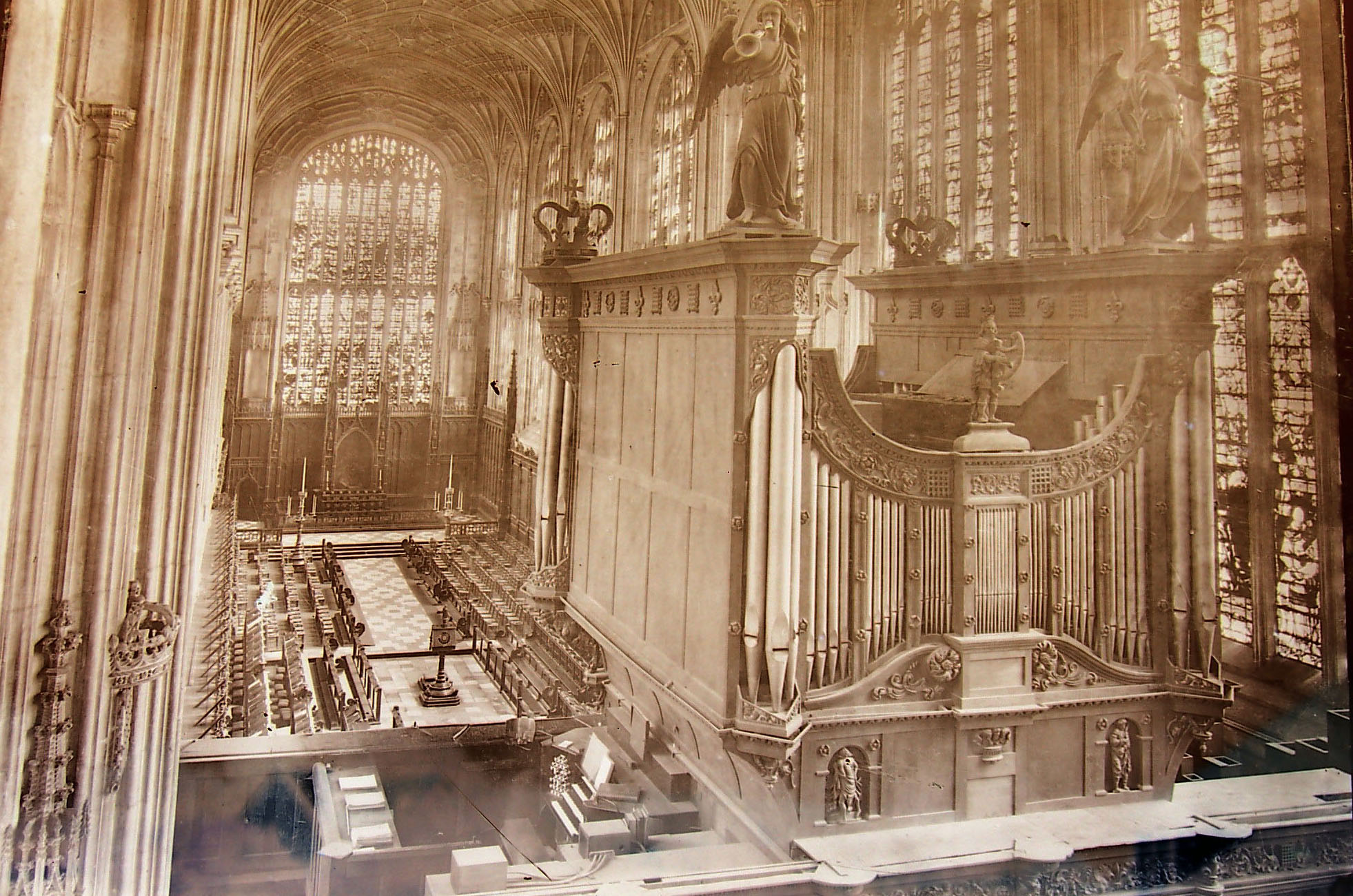

Front Pipes

Some of the east front pipes are collapsing and require significant attention. These pipes will be repaired as took place in 2009 for the west front, and all casepipes will be re-gilded.

Case

The case will be surveyed, cleaned and repaired as necessary. Asbestos will be removed from the south side of the screen. The angels on top of the main case will be re-gilded.

Revision of the Layout

A substantial revision of the organ's internal layout at console level will result in the Choir Organ being turned to face east, with a full-height shutter-front. The relocation of the Pedal chorus and Bourdon at this level will be an important outcome of this work. With a significant part of the Pedal Organ located in the case, the opportunity will be taken to provide a better layout in the south screen, benefitting both tonal balance and access.

Soundboards

The manual soundboards date from 1934 and have stood the test of time well, but they are susceptible to changes in temperature and humidity, and are showing signs of their age.

New slider soundboards will be installed throughout the organ, in the style of the existing ones, but with improved layouts, and the Choir Organ will go onto one rather than two soundboards as at present. The tables and upperboards will be constructed from man-made materials, which will not be affected by the vagaries of heat and humidity, and they will be grooved in the usual way, without slider seals.

Console

The console was last overhauled in 1992 and was further updated in 2009. It is, nevertheless, in quite a tired state.

The ivory key-coverings are still in good condition, but significant wear is present in the manual keyboards and pedal board.

After so many years of heavy use the time has come for new keyboards, transferring the old ivory and, where necessary, complementing this with additional reclaimed material.

The pedal board will be given a major overhaul and new contacts fitted throughout the console. New thumb piston units will be installed but the existing piston heads and stop knobs will be retained. The internal console woodwork is in good condition, but the jamb plates will be stripped and refinished.

A pedal divide facility will be added with new coupler and associated pistons.

New facilities will be added: Swell Unison Off, Great Reeds on Solo, and Great/Positive Exchange.

Action

Stop Action

The existing stop action utilises drawstop slider machines. With the provision of new soundboards these can be replaced with heavy-duty solenoids at the sliders, which are easy to maintain and take up much less space. They also offer the great benefit of quiet operation.

Electrical System

New low voltage power supplies will be installed as well as new cabling throughout the organ. New magnets will be installed throughout.

Wind System

All parts of the system will be overhauled and re-leathered.

Structure and Swell Boxes

Adjustments will be made to the building frame throughout the organ to accommodate the planned revision of the layout. The Choir Organ will have a new swell box and shutter front to suit the new layout, and the Swell and Solo shutter fronts will be overhauled. All mechanical swell-pedal linkages will be retained and modified in light of the alterations to the layout.

Performance Aids

General

An operation of this scale will include cleaning of the entire instrument and surrounding area. Attention will be given to all details necessary to leave the organ in first-class working order and establish its reliability for a further very long period.